I. Main features

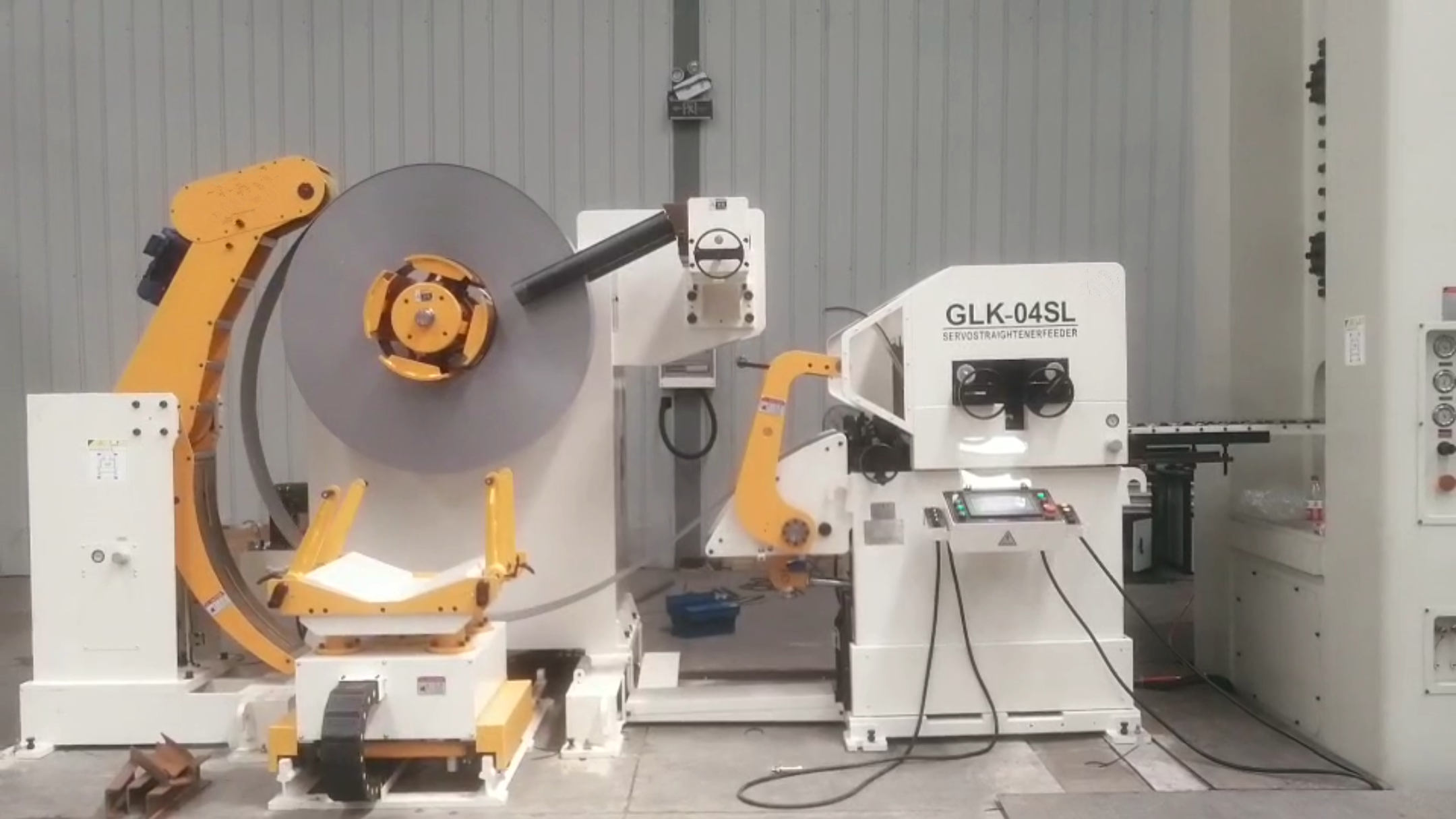

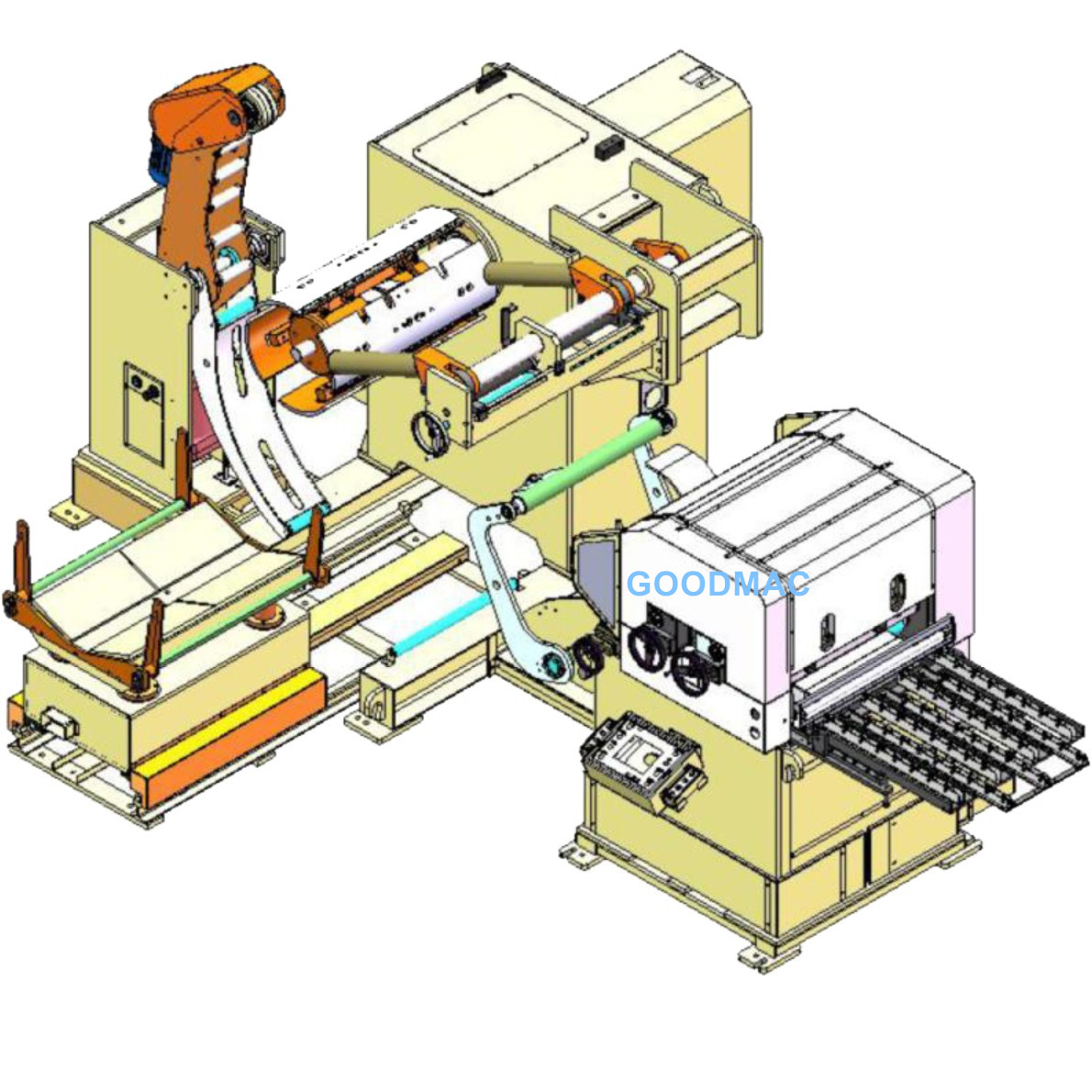

1. This GLK4 series coil feeding machine combines decoiler, straightener, and NC servo roller feeder together, so as 3 in 1.

As an integrated structure design, it can save workshop space obviously, as does not require a long metal sheet strip loop control.

2. It is a high intelligent machine, with a servo control system, a human–computer interface, and a self-diagnosis function etc.,

for convenient and safe operation, besides can protect users’ safe in press workshops.

3. It has a strong body structure with a reliable usage and a long service life indeed, for metal sheet stamping or cutting process.

4. An automatic supporting device and an automatic guiding device can support and guide applicable metal sheet strip into the straightener entrance easily.

5. Its straightening rollers are made of high-quality steels, with special heat treatment, with hardness HRC62 and high abrasion performance.

The upper rollers position can be adjusted by some worm gears easily. Through a servo motor drive, it can ensure a high precise straightening performance.

6. Some back pressure rollers can exert some powerful force for the upper straightening rollers and lower straightening rollers,

in order to achieve straightening rigidity and performance.

7. Through the servo motor drive and pneumatic pilot releasing, it can bring a precise feeding performance.

8. It can suit for various metal sheet coil material, such as cold rolled steel, hot rolled steel, galvanized steel etc.

9. Its coil car is optional, which can load a material coil to the decoiler automatically.

10. Other optional devices and non-standard devices can be equipped for your special requirement.

II. Specification parameter

| Model | GLK4-400 | GLK4-600 | GLK4-800 | GLK4-1000 | GLK4-1300 |

| Metal sheet coil width | 70-400mm | 70-600mm | 70-800mm | 70-1000mm | 70-1300mm |

| Metal sheet thickness | 0.6-6.0mm | ||||

| Coil weight maximum | 5000KGS | 5000KGS | 7000KGS | 7000KGS | 7000KGS |

| Coil inside diameter | Φ508mm | ||||

| Coil outside diameter | Φ1400mm | ||||

| Feeding speed | 0-24 m/min | ||||

| Feeding accuracy | ±0.15mm | ||||

| Straightener rollers | 7 pieces (upper 4 / lower 3) | ||||

| Feeding height | 1200±100mm | ||||

| Electrical power | 380V, 3 phase, 50HZ (or other) | ||||

| Pneumatic pressure | 5 kg/cm2 | ||||

| Decoiler mandrel expanding | hydraulic | ||||

| Decoiler motor | 2.2KW | 2.2KW | 3.7KW | 3.7KW | 3.7KW |

| Servo motor | 5.5KW | 7.5KW | 7.5KW | 11KW | 11KW |

III. Straightening capacity

(When material yield strength is 245N/mm², tensile strength is 392N/mm².)

| Model | GLK4-400 | GLK4-600 | GLK4-800 | GLK4-1000 | GLK4-1300 | |

| Metal sheet thickness × width (mm) | 0.6-1.3 | 400 | 600 | 800 | 1000 | 1300 |

| 2.0 | ||||||

| 2.3 | ||||||

| 2.5 | 1170 | |||||

| 2.8 | 933 | 933 | ||||

| 3.2 | 714 | 714 | 714 | |||

| 4.0 | 457 | 457 | 457 | 457 | ||

| 4.5 | 361 | 361 | 361 | 361 | 361 | |

| 5.0 | 293 | 293 | 293 | 293 | 293 | |

| 6.0 | 203 | 203 | 203 | 203 | 203 | |